(The Hammer)

The official Transmission of the Klingon Imperial Weapons Guild.

9804.15____________________________________________Vol.2/No.4 Part Two

As the Guild grows, we will try to enhance camaraderie by publishing histories

of our members (both Klingon and Terran). It is not necessary to develop a

family history to be a Guild member, but it does help to solidify an image of

you as a fellow crafts person and Klin.

The Five Blades

With tired hands K'Daq finished polishing the

last of the five weapons of honor (a tajtIq) and placed it alongside the other

four - an 'algnegh, a QIS, a jeqqIj and a 'aqleH. It was as if a tremendous

weight was lifted from his aged shoulders. Five weapons , five warriors, five

friends - each as different as the east is from the west but together they made

a formidable unified force. It was this force that had sustained the ancient

Klingon for so long.

Years ago K'Daq had undergone the Rite of MajQa. The

vision of his father had told him that it was not his place to join the Black

Fleet - that in Sto-Vo-Kor he would be known for his blades. For all eternity he

would supply blades for the greatest warriors of the Empire.

It seemed

rather disappointing at first. The Black Fleet was every warrior's right, but

after a time K'Daq realized that his spirit lived through each blade he created.

He was actually able to experience the Black Fleet from the viewpoints of

thousands of warriors. So his inevitable passing on to eternity was now an event

he looked forward to.

The five warriors would be guardians of his spirit

until he made the final journey. after which the blades would be there to guide

them and to free them to fight with the strength of a dozen

warriors.

Kri'stak, mountain of legend, I will miss you.

Next

month: I warned you. Unless you want to be subjected to more *hazy* memories of

life on the volcano - Send in your bios !! If you've sent one in and I didn't

post it, its been lost ......so send it again. I am finally settled with the new

computer so losses should be a thing of the past........SHOULD be.

The jey'naS or Klingon Double Headed Battle Axe

Like its smaller

brother the 'alngegh, the jey'naS is an ancient weapon - axes, in general,

having given way to blades more adaptable to the developing Klingon fighting

style. However many a warrior can be found who still understands and prefers the

axe in combat.

The jey'naS is a more massive weapon than it's smaller

brother. The double heads and longer shaft make it roughly twice as heavy as the

'alngegh. Reaction time will be slower while fighting with this weapon and for

that reason the addition of the *offensive* pommel has been made to prevent any

disadvantages.

Warriors who choose the axe in combat tend to be more

steadfast in their demeanor. Although they don't appear to be as *graceful* as

the typical sword fighter, appearances can be deceiving. Axe fighters don't

hesitate to take the fight directly to their opponent - there is very little in

the way of feints. Since the same muscles are developed in making blades at the

forge, smiths tend to choose the axe because of it's comfortable

familiarity.

Qa'Pla!!!

mupwI' yI'uchtaH !!

jey'naS - Klingon Double Headed Battle Axe

jey'naS Dimensions -

average:

Blade material -- G-2 titanium

thickness of blade -- .25

inches

length of blade -- 11 .50 inches.

width of blade -- 15.5

inches

Handle/ material -- 28 inch X1.5 inch dymondwood

shaft

Pommel -- 3 inch X 5/8th inch beveled titanium disc

Total

length -- 30.5 inches

weight -- 2.75 pounds

Next month : Mevak - Ceremonial Mauk To'Vor Dagger

bat'leth/SOK - Grinding to the final pattern, beveling and

polishing

This month we move along to *cleaning up* your rough cut

pattern, polishing the body of the weapon and placing cutting

bevels.

K'Beck touched on the initial grinding to pattern lines last

month but we'll expound on it a bit this month as well. No matter what method

you use to cut your pattern out, you will invariably be outside of your intended

pattern. Many times I draw up a pattern and when it is initially cut out I find

that I'd like to alter the blades arc or deepen one of the cut-outs - either for

esthetics or functional reasons. For this reason cleaning -up is a constant

order of business.

Options

The cheapest and most time intensive method would

involve the old hand file system. This might sound insane, but it is a time

tested method and can come in handy when you are short on cash for machines. If

using this method make sure your files are sharp and that your work piece is

securely fastened down to a bench surface. If the metal is even the least bit

loose, you will lose some of the files cutting ability. It is also important to

remember that most files cut on the push stroke. Dragging the tool back over the

edge only promotes damage to the teeth. It is important to gain confidence with

this technique because it will be used in many instances when power tools can't

gain access to a work area.

The next option is both reasonable in cost

and quite efficient - the bench mounted grinder. You can get a small bench

grinder for around $50 at most large hardware chains and if you check around you

can probably find one cheaper in the want ads. These use abrasives in a hard

wheel. They come in standard coarse/medium/fine grits and last through quite a

few blades. I use the coarse stone to clean to my pattern lines because it saves

expensive belts and I can get into tighter spaces with the wheels. A standard

wheel for a 6 inch grinder runs about $7.00 while a standard abrasive belt costs

about $4.50. One wheel will clean up many patterns and one belt will wear out

long before it cleans up one pattern. So the math leans you toward the grinding

wheel. You can also buy a *chuck* for the grinder and use it to mount grinding

*bits*, sandpaper drums/disks and abrasive shapes for refining your

work.

The last option is the belt grinder. If your pattern is fairly

close to the lines and you are anxious to get going you can grind to your lines

and start beveling at the same time. This is a more advanced technique since it

will make it hard to locate the blade's center line later. If your eye is

trained you can keep tabs on the center line while doing this. Otherwise it

procedes just like the grinding wheel

When cleaning to your pattern lines

it is a good idea to run your blade perpendicular to the grinding surface so

that you keep the edge square. If you hold the blade parallel to the wheel or

belt or file you might not be able to see the edge alignment and in doing so

grind past your pattern lines.......so keep an eye on how *square* your edges

are.

Because the bat'leth and the Sword of Kahless both have cut-outs

you will need to develope a technique to clean these interior areas as well. For

the file users there is no difference. For those using the grinding wheel you

can sometimes work it into the interior but it can be dangerous if the piece

*binds*. The belt grinder is almost worthless on interior areas unless you have

a very small wheel attachment and a long belt. These are found on the expensive

grinding machines.

A useful tool to work interiors is a drum sander

mounted in a drill. You can also put it in a drill press or use a table mounted

drum sander. In each of these cases you either clamp the metal down and bring

the drum to it or secure the drum and move the piece around. These give you a

clean and square edge on interiors as long as the drum fits into the cut-out.

You can get a variety of diameters of drums so this should cover almost every

situation. You can also buy stones mounted on shafts that fit in drills and

drill presses as well as *die grinders*. These act like the bench mounted

grinder only slower, but they get into restricted spaces.

Once your

pattern is where you want it I would suggest you polish the body of the blade

before doing any bevel work. This is for two reasons.

1. It squares the

edges and gives you a more accurate bevel placement.

2. It prevents

grinding into your bevel area when you are doing the *bulk* work.

Once

again you have a variety of options. Basically sandpaper is sandpaper whether it

is on a machine or in your hand. If you are using your hand be sure to put the

paper on a block to keep it square to the metal.....then just be patient and

work through the various grits. Which grit you start with depends on how rough

your metal's surface is to start with. If its pitted you'll need to start with a

50, 60 or 80 grit. Once you have the initial uniform surface created then its

only a matter of moving up the grits to the point at which you are satisfied (or

worn out). I usually polish to a 400 grit and then drop back to a 200 grit paste

on a buffing wheel to remove any grinding marks.

The machines available

for this operation are the various sanding machines. Palm sander, orbital

sanders, belt sanders etc. The palm and random orbital sanders usually make a

cleaner path without any *ditching*. The belt sander can remove material the

fastest but if used improperly it will trench your metal quickly. The important

things to remember about belt sanders is to keep them moving. Making even sweeps

of your blade in the same directions until the entire surface is gone over -

then repeat.

The table mounted belt grinder gives you the added stability

of getting to move the metal on the belt but it can also leave trenches if not

used properly.

Beveling

We've covered the process of beveling before and you

can refer back to the supplimentary article on that in the previous *mupwI'* by

using this link.

Bevels

I'd

like to stress another aspect of the bevels at this time and that is the design

and layout of the bevels themselves. Not all swords have cutting edges in the

same places. If you plan on moving your hands around on the blade during use,

you'd better not bevel too many surfaces. If you are happy to use the hand holds

then you can sharpen almost every edge on the weapon.

Recently K'Beck was

given instructions by local leaders in KAG to *dull* the edges of his weapons

due to an incident at a convention. You need to make sure you are aware of any

details concerning weapons at the convention you are attending before you find

your blade back in your car or confiscated by a con organizer. It might be your

proudest piece of work but it is a weapon and not everyone can be trusted with

sharp things at some events. Because of this, many events will exclude all

weapons so as not to offend anyone in particular.

At my first convention

I had made meqleths for both myself and my nine year old son but Texas A&M

didn't allow any type of weapon - even plastic toy guns. So all of that hard

work went for naught.

In general the bat'leth and Sword of Kahless have

sections of the edges used for blocking attacks and sections for making cuts.

The junction of two edges is usually left thick and acts as a blade *catcher*.

In many of Worf's fights he breaks the opponents weapon with this section of his

blade. I'm not sure that speaks too well for his opponent's blade

construction.

The Standard bat'leth and the Sword of Kahless

Patterns cleaned up/body polished/bevels placed

These are

terrible pictures. The weather out here has made photography difficult. As soon

as I get acceptable results I will update this section and notify you

all.

What you are looking at (if you could see it) are both weapons

polished and beveled.

Next month we will discuss handle options and

complete the weapons.

.

.

If

you'd like to get a head start on next month's work find some nice hard-wood or

large slabs of animal horn (if available). You can also use a wooden spacer and

wrap it with leather to give yourself a more comfortable grip while still

looking like the weapons on the shows.

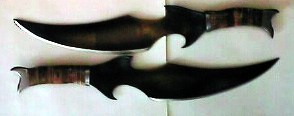

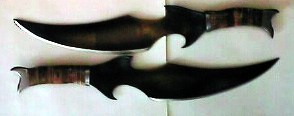

Bonus Weapons

To make up for the lousy photos I'm including the

finished tajtIq pair from *Apocalypse Rising*. With the blued blade and black

leather handles offset by the heavy titanium hardware - well.....I was a happy

old Klingon. Enjoy.

These are the blades with

their leather shaped prior to treatment with the lacquer.

.

.

I

used black lacquer to soak the leather this time. I liked the results.

mupwI' yI'uchtaH !!

*mupwI'* Volume 2/ Number 4/ Part One